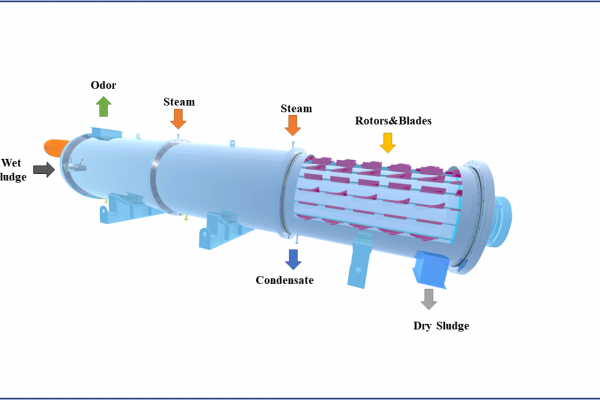

Thin Film Sludge Drying Technology

The drying process is essential in all types of sludge disposal methods. The thin film sludge dryer can be applied for municipal sludge, industrial sludge and chemical sludge drying. It can be combined with incineration, landfill and other technologies to meet the waste reduction as well as other resource requirements surrounding waste management.

For more information please visit www.kwi-intl.com

Technology of Sludge Drying Combined with Power Generation

In this particular application, the sludge from municipal sewage treatment plant is converted into biofuel by drying. The dry sludge is transported to a thermal power plant for power production. Meanwhile, the heat required for drying is the waste steam from the thermal power plant. The superiority of this application lies in the full use of social resources and social division of labor to solve sludge problem. It forms a complete market-oriented and sustainable development business application.

The sludge drying combined with power generation technology includes one-stage and two sludge drying processes.

One-stage Sludge Drying Process

The process mainly includes several units:

- Sludge receive, storage and transportation unit

- Sludge drying unit

- Tail gas treatment unit

- Biological/chemical deodorant unit

- Dry sludge storage and transportation unit

- Steam unit

- Electrical, instrument and control unit

In the one-stage sludge drying process, the sludge storage and drying is operated under closed negative pressure resulting in no odor. The drying process utilizes the advanced thin film sludge dryer, and recovers the heat of waste gas as well minimizes energy consumption and costs. In addition, the process is flexible, one-stage drying process can reduce moisture content to 30-45%.

Two-stage Sludge Drying Process

The process mainly includes several units:

- Sludge receiving, storage and feeding unit

- Primary thin film drying unit

- Waste gas and waste heat recovery unit

- Secondary belt drying unit

- Deodorant unit

- Dry sludge storage and transportation unit

- Steam unit

The two-stage sludge drying process completely uses the waste heat obtained from the primary drying system. With the integration of energy recovery, the operational costs can be reduced. In the process, the sludge in the plasticization stage is made into particles to avoid dust generation. With this two-stage drying process, the sludge can be completely dried. The operational temperature is below 110 ℃, which ensures the safety of the equipment and the operators.

Petrochemical Sludge Drying and Incineration Technology

In this application, the petrochemical sludge drying and incineration technology uses the advanced thin film sludge dryer to realize the high efficiency heat drying of sludge and effectively improve the calorific value of sludge. Thin film sludge dryer has an inert system, special seal structure and multiple emergency safety assurance measures can provide the system with high safety and reliability. In view of the characteristics of oily sludge, the two section incineration system of “rotary kiln and two combustion chambers” is used for the full combustion of all the combustible materials in the sludge. The system completely recovers the energy generated in the sludge incineration process, and uses it in thin film sludge dryer. Such an act enables the system to satisfy the vast majority of dry energy consumption. Using “dry and wet” method to treat the tail gas, tail gas standardized emissions is achieved.